خلاصہ

I have an experience in mechanical system for the detailed design & execution of HVAC & Plumbing systems. Possess in depth knowledge of proposal and planning, detailed HVAC design as per ASHRAE CODES, HVAC load calculation, ventilation calculation, ducting and piping layout, creating drawings, issuing BOQ, equipment selection, site supervision, Quantity surveying, Billing & verification, coordination & field engineering. Well aware of ASHRAE, SMACNA, ARAMCO & SEC international standards of HVAC design & its erection. Strong technical expertise of piping, pipe supports, valves, related components in related to construction, planning, fabrication, erection, welding, inspection and hydro testing. Talented at managing multi‐cultural team members and developing high performance teams

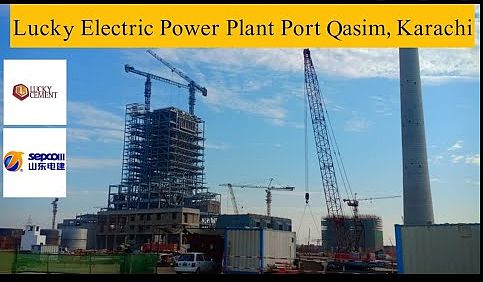

پراجیکٹس

تجربہ

Mechanical Engineer

General and Technical Site supervision of Civil and Mechanical works in installation pipeline including firefighting pipeline ,Domestic sewage pipeline ,portable pipeline irrigation and oily waste water pipeline including foundations and installation of HVAC work, installation chillers, axial fans, blower fans ,split and tower air- conditioning ,Hydro static and Gas tightness test packages associated works. Plan and execute Civil and Mechanical works in power plant Construction in coordination with Civil & Mechanical Contractors. Monitor progress of Civil & Mechanical Contractors as per the schedule agreed. Direct construction, operations, and maintenance activities at project site. Site inspection/audit of engineering works). Working closely with other discipline engineers, architects, designers and project managers as a key team player within an integrated multi-disciplinary project delivery team. Inspection of installation fire fighting pipeline and HVAC work. Hydro static test and Gas tightness test and walk down,punch list. MCC Packages ,Transmittal,MCC walk down,Punch list etc Inspection of water spray system and Foam system Communicating effectively with clients and internal team members in the design and specification development of plumbing building systems. Experience with pipeline construction techniques such as welding, excavation, and assembly. installation Screw chilled water and Air-Handling system, air-conditioning(AC) ,split and tower AC in coal power plants Coordination with client regarding site quires, Quality and progress issues. Complete knowledge of PPE's, and other safety equipment’s a/c to nature of job. Prepare fire protection system performance specifications Ensuring all documentation meets formal requirements and required standards Sorting, storing and retrieving electronic and hard copy documents on behalf of clients and industry professionals Producing document progress reports for senior managers Conducting regular reviews and document audi

POWER PLANT ENGINEER

Maintenance engineer in coal ash handling system

Supervised ash conveyance and coal handling plants. Monitored operating supply delivery. Coordinated and led company safety training programs. Maintained and monitored process thermopac and power boilers

Wet ash system:Bottom ash (w-type and 3V type Hopper ) High concentration slurry

disposal system and Ash slurry series . Wet ash unloading and slurry disposal system (silo to ash pond)

Fly ash system: ESP/APH/DUCT (wet and dry system &Buffer hopper ash

conveying ,Densive lean phase) D-pump ,nova & Air lock vessel . Planning and co-ordination of all activities for operation maintenance of ash handling

system. Looking after every kind of breakdown ,corrective preventive maintenance &modification

work of complete ash handling plant

To make sure the work quality and safety

Manpower handling and proper utilization.

MECHANICAL ENGINEER

Preparing and emailing of daily, weekly and monthly Progress reports,Work

schedule Charts updating to PM for Ongoing activities. Ensure that the site works are performed in an efficient and safe manner

within contract guidelines, schedule and contractspecification

Assigning duties to various staff members and keeping a watch on theirperformances. Planning and managing the resources, equipments, required for project execution

Coordination with store/material coordinator for related job

Coordination with client regarding site quires, Quality and progressissues. Focus to avoid the rework Follow up with the engineering department for the issuance of constructiondrawings. Identification of the work front availability. Complete knowledge of PPE's, and other safety equipments a/c to nature of job. Experienced in fabrication activities of piping and steel structure. Experienced in errection activities of piping and steel structure. Complete study of the job scope in all aspects & prepare strategy to execute the job. Assigning duties to various staff members and keeping a watch on their performances. Planning and managing the resources, equipment’s, required for project execution. Coordination with store/material coordinator for related job. Coordination with client regarding site quires, Quality and progress issues. Complete knowledge of PPE's, and other safety equipment’s a/c to nature ofjob

Internee

Internee

Managed power plant maintenance, fuel distribution, energy conservation projects, system upgrades and mechanical construction, with a focus on process optimization and reliability.